Electrical energy conversion relies heavily on power electronics and semiconductor devices. These workhorses silently transform voltage and current levels, enabling efficient and reliable operation of everything from the humble smartphone charger to the massive power grids that keep our cities lit.

However, traditional silicon-based power electronics face limitations that hinder further advancements. This is where wide-bandgap (WBG) semiconductors step in, promising a brighter future for power electronics.

The Challenges of Silicon

Silicon, the workhorse of the electronics industry, faces limitations in high-power applications. These limitations include:

- High Switching Losses: Frequent on-and-off cycles in power electronics devices generate heat due to internal resistance. Silicon’s limitations lead to higher switching losses, reducing overall efficiency and requiring bulky heat sinks. A study by the National Renewable Energy Laboratory (NREL) found that switching losses in silicon inverters for solar power systems can account for up to 5% of the total energy generated.

- Limited Temperature Tolerance: Silicon’s maximum operating junction temperature is typically around 150°C. Operating Si FETs at higher temperature has its own disadvantages as mentioned in the journal paper

- Voltage Limitations: The typical breakdown voltage for silicon devices is around 600V. This limits their use in high-voltage applications like power grids and electric vehicle fast chargers.

These challenges translate to bulky, less efficient power electronics systems, hindering advancements in areas like renewable energy integration, electric vehicles, and high-power industrial applications.

Enter Wide-Bandgap Semiconductors

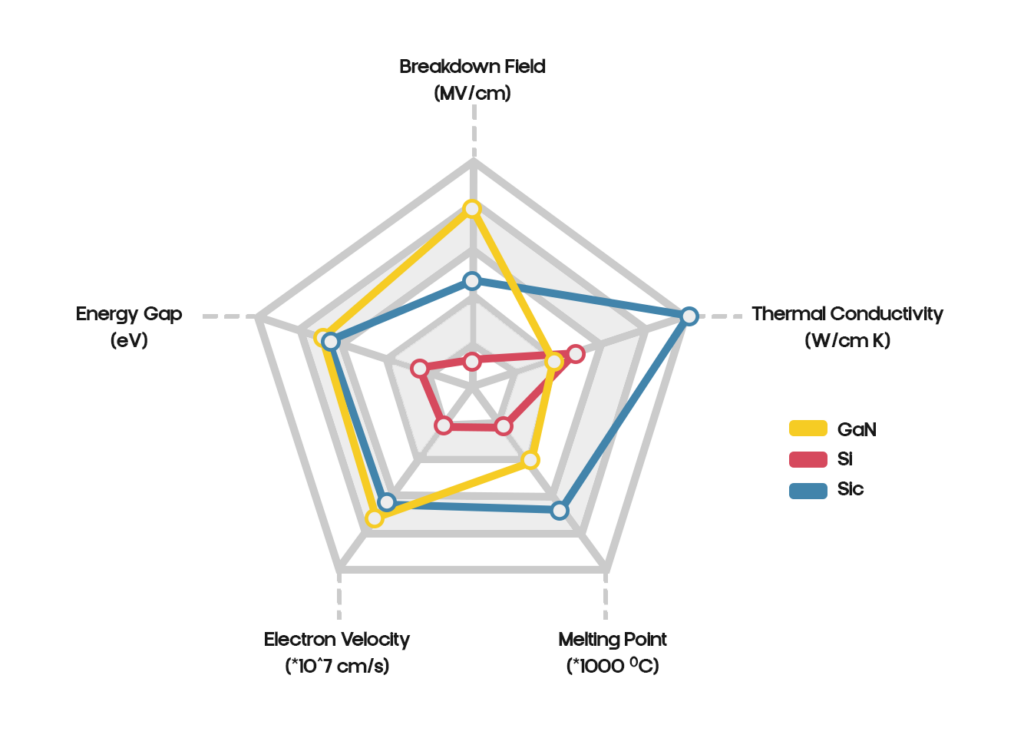

Wide bandgap (WBG) semiconductors offer a compelling solution. Here’s why:

- Superior Material Properties: WBG materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) boast wider bandgaps compared to silicon. This translates to higher breakdown voltages, enabling them to handle higher voltages and operate at elevated temperatures with minimal performance degradation.

- Reduced Switching Losses: WBG materials have superior electrical properties, leading to lower on-resistance and significantly reduced switching losses. This translates to higher efficiency and more compact designs.

- Faster Switching Speeds: WBG materials offer higher electron mobility, enabling faster switching speeds. This is crucial for high-frequency applications like electric vehicle inverters and power supplies for data centers.

WBG semiconductors hold immense potential to revolutionize power electronics, leading to:

- Increased Efficiency: Reduced switching losses translate to significant energy savings across various applications. A report by Yole Développement, a market research firm, projects that WBG semiconductors can improve the efficiency of power electronics systems by up to 20% compared to silicon.

- Reduced System Size and Weight: Smaller, more efficient devices enable compact and lightweight power electronics systems. A report in Journal of the Korean Ceramic Society found that using SiC inverters in electric vehicles can reduce inverter size and weight by up to 50% compared to silicon inverters.

- Higher Power Densities: WBG devices can handle higher voltages and currents, allowing for higher power density systems. Wolfspeed, a leading manufacturer of SiC devices, states that SiC devices can achieve three times higher power density compared to silicon devices.

- Improved System Reliability: WBG’s superior thermal performance leads to more reliable operation in harsh environments.

The Crucial Role of Modeling

Power semiconductor device modeling plays a vital role in unlocking the potential of WBG technology. Here’s why:

- Virtual Prototyping: Modeling allows engineers to virtually test and optimize device designs before fabrication, saving time and resources.

- Predicting Performance: Models can predict device behavior under various operating conditions, ensuring reliable and efficient system design.

- Improved Design Techniques: Modeling helps engineers develop innovative device structures and optimize existing ones to maximize WBG technology’s benefits.

Several modeling approaches exist, with varying levels of complexity. The choice of model depends on the specific application and the level of detail required.

Beyond Modeling: LiveBench and the Future of WBG Evaluation

Power semiconductor device modeling plays a vital role in unlocking the potential of WBG technology, but it’s just the first step. Here’s where platforms like LiveBench come into play:

- Digitalizing Component Evaluation: LiveBench goes beyond traditional modeling by offering a cloud-based platform for digitalizing component evaluation. This platform leverages real-world hardware test benches, enabling engineers to test and analyze actual WBG devices under various operating conditions.

- Cloud-based Scalability and Collaboration: LiveBench operates in the cloud, allowing for remote access, scalability, and collaborative work on device evaluation. This facilitates faster development cycles and knowledge sharing among engineers across geographical locations.

- Data-driven Insights: LiveBench integrates with test benches, capturing real-time data from WBG devices. This data can be analyzed to gain deeper insights into device behavior, validate models, and optimize performance in real-world scenarios.

Essentially, LiveBench bridges the gap between traditional modeling and physical testing. It provides a powerful tool for:

- Validating Model Accuracy: By comparing model predictions with real-world data from LiveBench, engineers can ensure the accuracy of their models and refine them for better design optimization.

- Accelerated Development Cycles: LiveBench’s digital evaluation capabilities streamline the testing process, leading to faster development cycles for WBG-based power electronics systems.

- Optimizing Device Performance: The data and insights from LiveBench can be used to optimize device design for specific applications, maximizing the benefits of WBG materials.

A New Era of Power Electronics

The limitations of silicon-based power electronics are creating a fertile ground for a WBG revolution. Wide bandgap semiconductors like SiC and GaN offer significant advantages in terms of efficiency, performance, and reliability. Powerful modeling tools provide the foundation for unlocking this potential by enabling virtual prototyping and device behavior prediction. However, for true innovation, the digital world must connect with the physical one.

Platforms like LiveBench represent a crucial step forward in WBG evaluation. By offering a cloud-based platform for digitalizing component evaluation through real-world hardware testing, LiveBench bridges the gap between modeling and physical verification. This combined approach empowers engineers to validate models, accelerate development cycles, and optimize device performance for real-world applications.

In conclusion, the future of power electronics is bright, fuelled by the exceptional properties of WBG semiconductors and the power of advanced modeling and evaluation tools like LiveBench. Together, they hold the key to unlocking a new era of efficient, compact, and reliable power electronics that will power the technologies of tomorrow.

Upcoming Lab

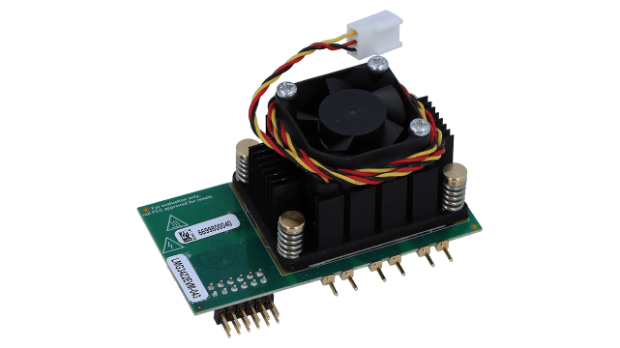

Stay tuned to test and analyze the voltage and thermal stress on TI’s GaN switches – LMG3422. User will be able to explore the thermal performance of these switches when driven at nearly 1 kW, observing how the on-board cooling fan reduces thermal stress for optimal operation. Additionally, they will have the opportunity to test the on-board deadtime feature.

Lab features:

Users can set the input operating voltage, adjust the switching frequency and duty cycle, control the cooling fan to observe the thermal effect on the GaN devices and observe the switching waveform and real time thermal data.