In the booming robotic vacuum market—valued at $11.14 billion in 2025 and projected to reach $35.56 billion by 2035 with a 12.3% CAGR—motor control is pivotal for delivering efficient, quiet, and autonomous cleaning. At TenXer Labs, we provide reference designs that help system design engineers overcome challenges in navigation, sensing, and power management while focusing on robust motor control. This guide offers a detailed reference design for robotic vacuum motor control, including block diagrams, component comparisons, and optimization strategies. Whether you’re designing wheel drives for precise movement or suction fans for powerful cleaning, this reference design blueprint will accelerate your development and ensure compliance with standards like IEC 60335 for safety.

Understanding Robotic Vacuum Motor Control: Key Requirements and Challenges

A robotic vacuum’s motor control system manages multiple BLDC motors for wheels, brushes, and suction, balancing torque, speed, and efficiency. Key requirements include:

- Efficiency: >85% to achieve 90-120 minute runtimes on 2600mAh Li-ion batteries.

- Noise Reduction: <40dB for quiet operation in homes.

- Reliability: Sensorless startup in stalled or windmilling conditions.

- Integration: Compact designs with I²C for tuning and feedback.

Challenges like vibration from high-RPM fans (20,000-35,000 RPM) or stalls on carpets demand advanced techniques like field-oriented control (FOC). Our reference design addresses these with modular blocks, reducing development time by 40-60%.

Block Diagram for Multi-Motor Robotic Vacuum Reference Design

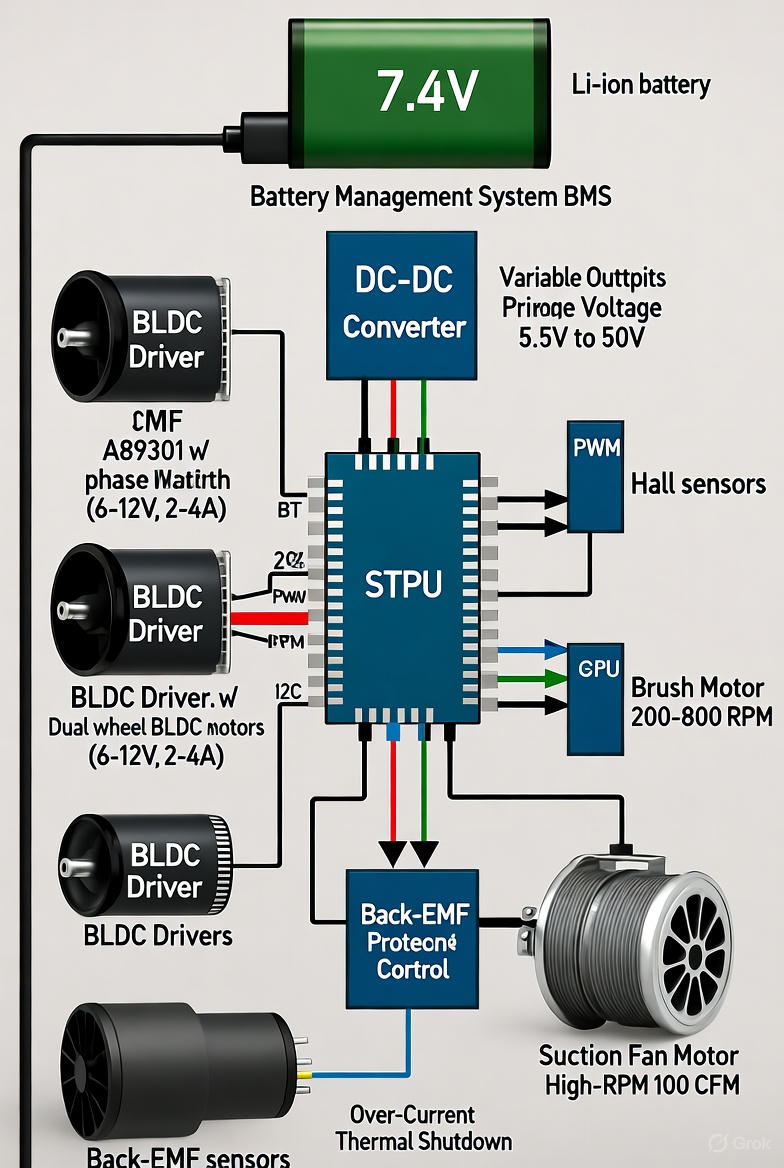

The reference design features a central MCU coordinating power, control, and feedback. Here’s a high-level block diagram description :

- Power Input: 7.4V Li-ion battery with BMS → DC-DC converters (e.g., 5.5-50V output for motors).

- Central Controller: STM32 MCU with PWM/I²C interfaces.

- Motor Drivers: Integrated ICs (e.g., A89301) for phase control.

- Feedback Loop: Hall sensors or back-EMF for closed-loop speed/torque.

- Outputs: Dual wheel BLDC (6-12V, 2-4A), brush motor (200-800 RPM), suction fan (high-RPM, 100 CFM).

- Protections: Over-current, thermal shutdown, lock detection.

Wheel Motor Control Reference Design: Mobility and Odometry

Wheel motors provide traction and steering in robotic vacuum reference designs. Recommended: Dual 6-12V BLDC motors (100 RPM, 0.5A no-load) with encoders.

- Control Strategy: PWM (1-20kHz) for variable speed; trapezoidal commutation for initial torque.

- Reference Implementation: Differential drive—MCU adjusts left/right speeds for turns (e.g., 50% left for right pivot). Integrate odometry via encoders for SLAM feedback.

- Optimization: Torque limiting via current sensing prevents 15% power waste on obstacles.

Comparative Options:

Driver | Provider | Voltage/Current | Features | Best For |

A89301 | Allegro | 5.5-50V, 11A peak | Sensorless FOC, I²C tuning | Premium, low-noise mobility |

DRV10983 | TI | 8-28V, 3A | Sinusoidal control, auto-tuning | Mid-range, cost-effective |

STSPIN32F0 | ST | 8-45V, 1A | Integrated MCU, EEPROM | Compact prototypes |

Brush and Suction Fan Motor Control Reference Design

Brush motors agitate debris, while suction fans create vacuum pressure—both require high torque and variable speed.

- Brush Reference: 12V BLDC (300 RPM) with trapezoidal mode for low-speed operation. Monitor current spikes for tangle detection.

- Suction Reference: 24V centrifugal fan (15,000-35,000 RPM) with rapid acceleration (<200ms). Duty cycle control (30-100%) for modes like “turbo.”

- Reference Implementation: Back-EMF sensing for sensorless commutation, eliminating halls and reducing quiescent current to <50μA.

- Noise Mitigation: FOC cuts acoustic levels by 15dB, crucial for user comfort.

Comparative Fans/Motors:

Controller | Provider | RPM Range | Features | Efficiency | Application Notes |

Allegro | Up to 35,000 | QuietMotion EMI reduction, over-current protection | 90%+ | Superior for low-noise suction in home environments | |

MCT8316A | TI | 20,000-30,000 | Diagnostic features, 20% lower cost | 85-90% | Mid-range brush control with built-in regulators |

STSPIN32F0 | ST | 15,000-25,000 | Standalone operation, 30% BOM savings | 85% | Entry-level fans with EEPROM for parameter storage |

Power Management and Integration in Robotic Vacuum Motor Control Reference

Efficient power distribution is key to this reference design.

- Battery Reference: 7.4V 2600mAh LiPo with BMS for overcharge protection.

- Conversion: Step-up converters (e.g., TI TPS61088) for motor voltages, minimizing losses (3-5%).

- Integration Tip: Shared I²C bus for driver tuning (speed, resistance) and feedback, cutting BOM by 20-25%.

Comparative Batteries:

Model | Capacity | Runtime | Cost Impact |

Eufy E20 | 2600mAh | 60-70 min | Low, efficient for entry-level |

Roborock Z70 | 6400mAh | 300 min | High, premium with fast charge |

Duty-cycling extends life by 20-30%, aligning with IEC standards.

Bumper Sensing Integration for Vacuum Motors

Integrate Hall-effect sensors for impact detection and position monitoring in the robotic vacuum motor.

- Reference: Use Hall sensors (e.g., Allegro APS11753) for reliable edge detection and obstacle alignment.

Comparative Sensors:

| Parameter | APS11753 | TMAG5273 |

|---|---|---|

| Power Consumption | 3.1 µA (micropower mode) | 1 µA – 2.3 mA (depending on mode) |

| Operating Voltage Range | 2.2 V – 5.5 V | 1.7 V – 3.6 V |

| Startup / Configuration | Simple digital output, no setup required | Requires I²C configuration |

| Operating Temperature | –40 °C to +125 °C | –40 °C to +125 °C |